HDPE Pipe jointing methods

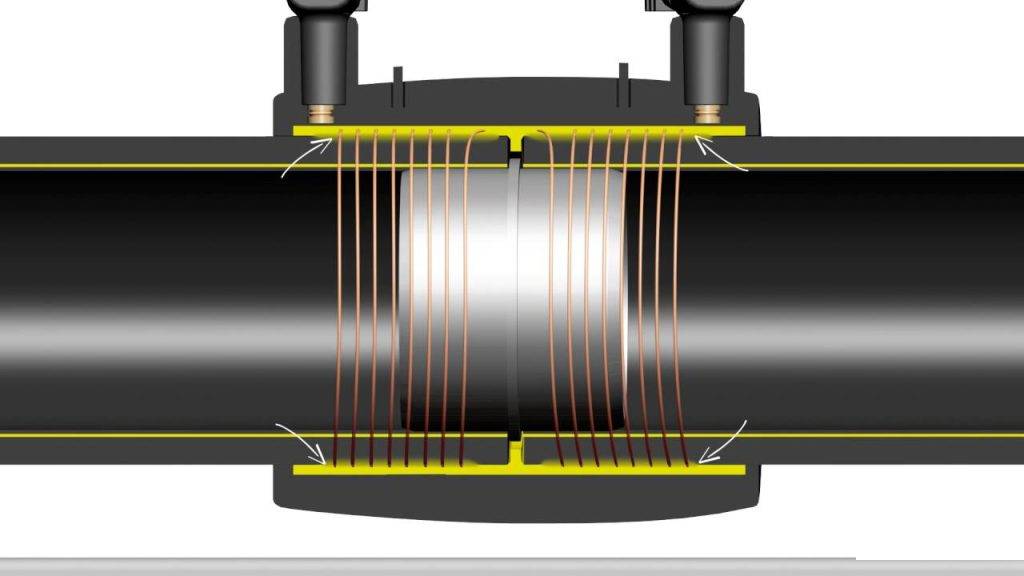

Electro Fusion Welding

Electrofusion is a simple method of joining PE pipes in circumstances where butt fusion is not practicable, such as where valves, elbows, and tees must be added. Prefabricated fittings are used, incorporating an electrical heating coil which melts the plastic of both the fitting and the pipe, causing them to fuse together.

The characteristics of the fitting to be welded, such as the fusion time, are registered via a barcode on the fitting. An electrofusion control unit (ECU) supplies the electrical energy necessary to heat the coil. When the coil is energized, the material adjacent to it melts and forms an expanding pool which comes into contact with the surface of the pipe. The continued introduction of heat energy causes the pipe surface to melt, and a mixing of pipe melt and fitting melt takes place; this is vital to produce a good weld. Following the termination of the heat cycle, the fitting and the pipe are left to cool, and the melted material solidifies to form a sound joint.

The effectiveness of electrofusion depends on attention to preparation of the jointing surfaces and ensuring that the surfaces to be welded have satisfactory contact during the welding and cooling cycles. The pipe surfaces to be fused need to be scraped to remove the surface oxidation layer prior to fusion. Pipe clamps or other approved methods of restraining, aligning and re-rounding the pipes during the fusion cycle should be used.

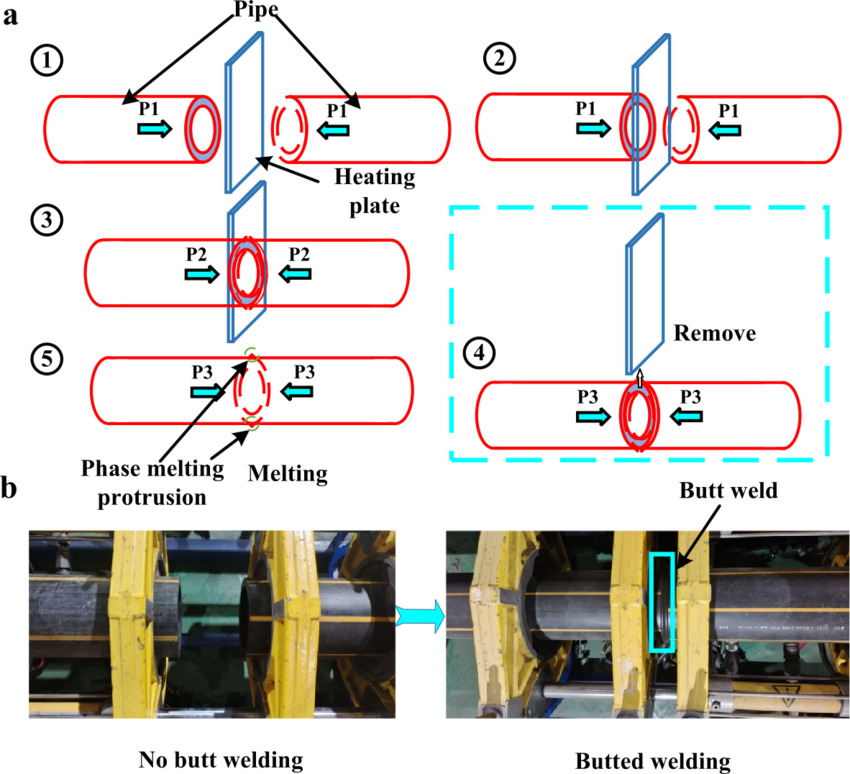

Butt Fusion Welding

Butt fusion is a thermo-fusion process. Butt fusion involves the simultaneous heating of the ends of two pipe/fitting components which are to be joined, until a molten state is attained on each contact surface.

The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogeneous fusion joint is formed. The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself.

An electrical heater plate is used to raise the temperature of the pipe ends to the required fusion temperature.

The following parameters are controlled:

- heater plate temperature

- ovality and alignment

- interface pressure

- bead width

- heat soak time

- changeover time

Socket Fusion welding

Socket fusion welding is a widely used technique for assembling plastics piping systems using injection molded fittings. Operating principles are straightforward, the welding cycle essentially consisting of a heating phase and a cooling/welding phase.

A metal socket mounted on a hot plate heats the outside circumference of the pipe (see process schematic below). Heating occurs along a defined length which will vary depending on the size of pipe and fitting being welded. A metal spigot on the opposite side of the hot plate simultaneously heats the inside surface of the injection molded fitting. The length of the heated region is the same as that for the pipe.

Both fitting and pipe are heated for a set length of time after which the heated socket/spigot tooling is removed, and the pipe is pushed into the fitting. Pipe and fitting are left for a predetermined time to cool and form a weld.

Depending on the size of pipe, socket fusion welding can either be done by hand or carried out on a manually operated machine.